Ajust. Toleràncies ISO#

Pàgina en desenvolupament

Encara estem treballant en aquest document.

Esperem oferir-vos properament el seu contingut.

Disculpeu les molèsties.

Normativa ISO#

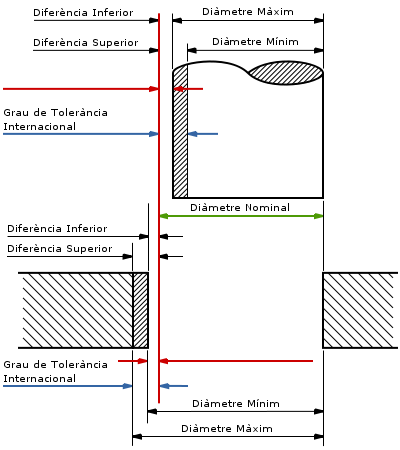

Quan especifiquem el diàmetre d’una peça que ha d’encaixar amb una altra cal tenir en compte si aquesta peça podrà girar lliurament dintre de l’altra o ha d’anar incrustada. Per això cal donar la tolerància de les peces. La normativa ISO utilitza una lletra (majúscula per forats, minúscula per eixos) i un nombre per especificar la tolerància en funció del diàmetre nominal de la peça.

Eix |

0<Ø≤3 |

3<Ø≤6 |

6<Ø≤10 |

10<Ø≤18 |

18<Ø≤24 |

24<Ø≤30 |

30<Ø≤40 |

40<Ø≤50 |

50<Ø≤65 |

65<Ø≤80 |

80<Ø≤100 |

100<Ø≤120 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

c11 |

−0.060 |

−0.070 |

−0.080 |

−0.095 |

−0.110 |

−0.110 |

−0.120 |

−0.130 |

−0.140 |

−0.150 |

−0.170 |

−0.180 |

d9 |

−0.020 |

−0.030 |

−0.040 |

−0.050 |

−0.065 |

−0.065 |

−0.080 |

−0.080 |

−0.100 |

−0.100 |

−0.120 |

−0.120 |

f7 |

−0.006 |

−0.010 |

−0.013 |

−0.016 |

−0.020 |

−0.020 |

−0.025 |

−0.025 |

−0.030 |

−0.030 |

−0.036 |

−0.036 |

g6 |

−0.002 |

−0.004 |

−0.005 |

−0.006 |

−0.007 |

−0.007 |

−0.009 |

−0.009 |

−0.01 |

−0.01 |

−0.012 |

−0.012 |

h6 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

h7 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

h9 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

h11 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

k6 |

+0.006 |

+0.009 |

+0.010 |

+0.012 |

+0.015 |

+0.015 |

+0.018 |

+0.018 |

+0.021 |

+0.021 |

+0.025 |

+0.025 |

n6 |

+0.010 |

+0.016 |

+0.019 |

+0.023 |

+0.028 |

+0.028 |

+0.033 |

+0.033 |

+0.039 |

+0.039 |

+0.045 |

+0.045 |

p6 |

+0.012 |

+0.020 |

+0.024 |

+0.029 |

+0.035 |

+0.035 |

+0.042 |

+0.042 |

+0.051 |

+0.051 |

+0.059 |

+0.059 |

s6 |

+0.020 |

+0.027 |

+0.032 |

+0.039 |

+0.048 |

+0.048 |

+0.059 |

+0.059 |

+0.072 |

+0.078 |

+0.093 |

+0.101 |

u6 |

+0.024 |

+0.031 |

+0.037 |

+0.044 |

+0.054 |

+0.061 |

+0.076 |

+0.086 |

+0.106 |

+0.121 |

+0.146 |

+0.166 |

Forat |

0<Ø≤3 |

3<Ø≤6 |

6<Ø≤10 |

10<Ø≤18 |

18<Ø≤24 |

24<Ø≤30 |

30<Ø≤40 |

40<Ø≤50 |

50<Ø≤65 |

65<Ø≤80 |

80<Ø≤100 |

100<Ø≤120 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

C11 |

+0.120 |

+0.145 |

+0.170 |

+0.205 |

+0.240 |

+0.240 |

+0.280 |

+0.290 |

+0.330 |

+0.340 |

+0.390 |

+0.400 |

D9 |

+0.045 |

+0.060 |

+0.076 |

+0.093 |

+0.117 |

+0.117 |

+0.142 |

+0.142 |

+0.174 |

+0.174 |

+0.207 |

+0.207 |

F8 |

+0.020 |

+0.028 |

+0.035 |

+0.043 |

+0.053 |

+0.053 |

+0.064 |

+0.064 |

+0.076 |

+0.076 |

+0.090 |

+0.090 |

G7 |

+0.012 |

+0.016 |

+0.020 |

+0.024 |

+0.028 |

+0.028 |

+0.034 |

+0.034 |

+0.040 |

+0.040 |

+0.047 |

+0.047 |

H7 |

+0.010 |

+0.012 |

+0.015 |

+0.018 |

+0.021 |

+0.021 |

+0.025 |

+0.025 |

+0.030 |

+0.030 |

+0.035 |

+0.035 |

H8 |

+0.014 |

+0.018 |

+0.022 |

+0.027 |

+0.033 |

+0.033 |

+0.039 |

+0.039 |

+0.046 |

+0.046 |

+0.054 |

+0.054 |

H9 |

+0.025 |

+0.030 |

+0.036 |

+0.043 |

+0.052 |

+0.052 |

+0.062 |

+0.062 |

+0.074 |

+0.074 |

+0.087 |

+0.087 |

H11 |

+0.060 |

+0.075 |

+0.090 |

+0.110 |

+0.130 |

+0.130 |

+0.160 |

+0.160 |

+0.190 |

+0.190 |

+0.220 |

+0.220 |

K7 |

0.000 |

+0.003 |

+0.005 |

+0.006 |

+0.006 |

+0.006 |

+0.007 |

+0.007 |

+0.009 |

+0.009 |

+0.010 |

+0.010 |

N7 |

−0.004 |

−0.004 |

−0.004 |

−0.005 |

−0.007 |

−0.007 |

−0.008 |

−0.008 |

−0.009 |

−0.009 |

−0.010 |

−0.010 |

P7 |

−0.006 |

−0.008 |

−0.009 |

−0.011 |

−0.014 |

−0.014 |

−0.017 |

−0.017 |

−0.021 |

−0.021 |

−0.024 |

−0.024 |

S7 |

−0.014 |

−0.015 |

−0.017 |

−0.021 |

−0.027 |

−0.027 |

−0.034 |

−0.034 |

−0.042 |

−0.048 |

−0.058 |

−0.066 |

U7 |

−0.018 |

−0.019 |

−0.022 |

−0.026 |

−0.033 |

−0.040 |

−0.051 |

−0.061 |

−0.076 |

−0.091 |

−0.111 |

−0.131 |

Tipus d’ajust#

Bàsicament existeixen 3 tipus d’ajust:

Joc: el forat és sempre més gran que l’eix, permet que l’eix llisqui o giri dintre del forat

Serratge: el forat és sempre més petit que l’eix, cal fer força o escalfar per muntar o desmuntar la unió.

Indeterminat: les toleràncies no permeten definir el tipus d’ajust. Normalment es tracta de sistemes mal dissenyats.

En el cas del joc podríem matisar el cas en el que la peça encaixa amb un mínim marge, per exemple una clau Allen dintre del cap d’un cargol d’aquest tipus. Aleshores parlem d”ajust d’ubicació.

Trobareu informació més detallada a l’article Engineering fit de la Wikipedia